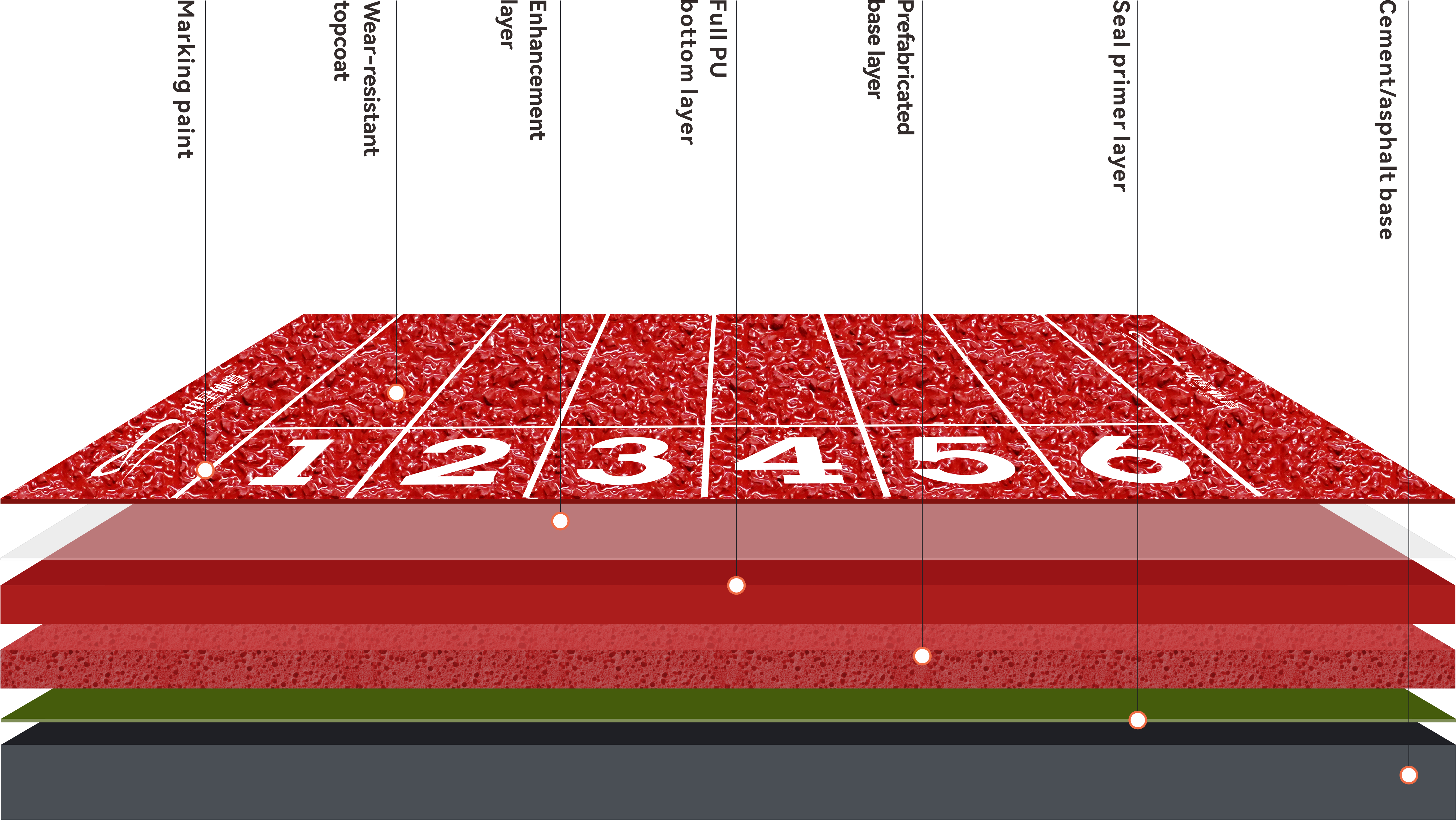

With natural rubber and synthetic rubber as the base material, mixed with natural mineral fillers, stabilizers and colorants, it is continuously calendered and mechanically embossed on an automated production line, and vulcanized under high temperature of 200-300℃ to form a double-layer structure with consistent textures, that is, a weather-resistant and abrasion-resistant colored surface layer and an elastic concave shock-absorbing bottom layer.

With natural rubber and synthetic rubber as the base material, mixed with natural mineral fillers, stabilizers and colorants, it is continuously calendered and mechanically embossed on an automated production line, and vulcanized under high temperature of 200-300℃ to form a double-layer structure with consistent textures, that is, a weather-resistant and abrasion-resistant colored surface layer and an elastic concave shock-absorbing bottom layer.

1、NOutstanding performance advantages

2、Integrated and seamless

3、Controllable construction period

1. Foundation inspection

2. Ground treatment

3. Adhesive application

4. Roll material laying

5. The main materials of the runway

6. Surface layer construction

7. Marking paint

8. Site acceptance